Classic lifts was approached by The Humber Bridge Board and their lift consultant to provide a modernisation package for the two specialist lifts in the Hessle and Barton Towers of the Humber Bridge. These lifts serve the full height of the towers and provide access for the engineering staff who conduct safety and essential maintenance works on the Grade 1 Listed bridge structure and as these units were nearly 40 Years old and reaching the end of their useful life, major works were required.

Classic Lifts submitted a proposal and programme to carry out the full modernisation of the lifts in late 2019 and appointed as Main Contractor to carry out the lift works which included the replacement of all major components with state of-the-art technology bringing the equipment up to the current Health and Safety Standards and to ensure reliability for many years to come.

The special and confined dimensions of the Bridge Towers brought two interesting and challenging engineering features in that the lifts have the highest travel of any project installed or modernised by Classic Lifts to date and probably the smallest load carrying capacity. Carrying out this highly technical modernisation was further compounded by the COVID-19 outbreak, but through excellent cooperation and help from the client and consultant throughout the works programme, Classic Lifts staff continued to work throughout the Pandemic to ensure the down time of the lifts was minimised.

In May 2019 Classic lifts were approached by The Humber Bridge Board and TÜV SÜD Dunbar Boardman to provide a modernisation package for the two engineers lifts in the Hessle and Barton Towers of the Humber Bridge, the lifts were approaching 40 Years old and were reaching the end of their useful life. A cost to carry out the full modernisation of the lifts was submitted and in October of 2019 Classic were appointed as Main Contractor to carry out the lift works.

The works included the replacement of all major components with state-of-the-art equipment to bring the lifts up to the current Health and Safety Standards and to ensure reliability for many years to come.

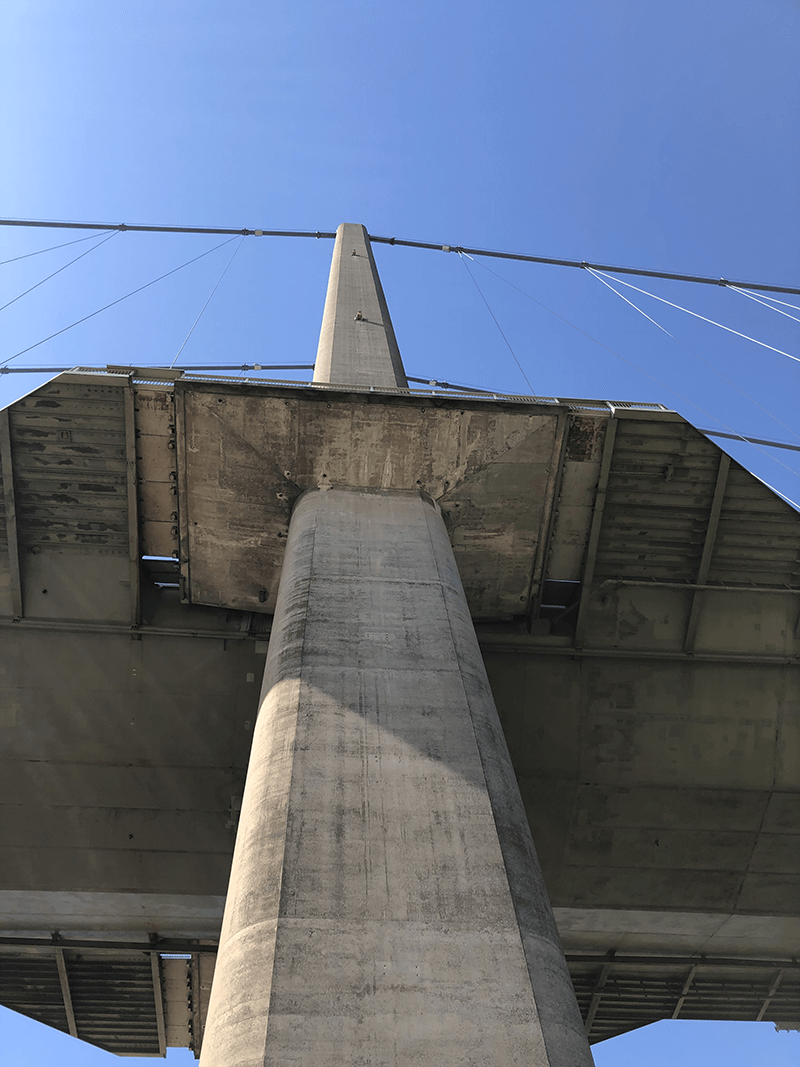

The lifts serve the full height of the towers and are used for the vital maintenance of the Grade 1 Listed structure.

The lifts have the longest travel of any lift installed or modernised by Classic Lifts and are probably the smallest load carrying capacity, these two features ensured the project was both interesting and challenging.

Carrying out this highly technical modernisation was further compounded by the Covid 19 outbreak, Classic Lifts continued to work throughout the Pandemic to ensure that the down time of the lifts was minimised.

Thanks to the client and consultant for their help and cooperation throughout the works but not forgetting the Classic Team who turned this modernisation into a successful engineering project despite the many obstacles.

Facts about the Bridge.

- The bridge crosses the Humber Estuary between Hessle, East Yorkshire and Barton upon Humber, North Lincolnshire.

- The bridge was the world’s longest single-span suspension bridge when it opened and held this record for 16 years.

- It is the UK’s longest single-span suspension bridge and now the eighth longest in the world.

- It remains the longest in the world that can be crossed on foot or by cycle.

- The bridge is made up of three spans; Hessle side span (280 metres), Barton side span (530 metres) and the main centre span (1410 metres) making a total of 2,200 metres or 1.4 miles.

- The road deck, which is made up of 124 steel box sections weighing over 17,000 tonnes is designed as an upside-down aircraft wing, to help keep the deck stable during high winds.

- The concrete towers are 155.5 metres (510 feet) tall and were built to be 36mm further apart from each other at the top than at the bottom, to allow for the curvature of the Earth.

- There is enough wire used in the bridge to go around the Moon more than six times.

- The bridge is open 24 hours a day, seven days a week, 365 days a year.

- In February 2002, the 100 millionth vehicle crossed the bridge as part of the 6 million crossings that year. The bridge is now carrying more than 10 million vehicles every year.

Contact the team: